Mercedes Rear Wheel temperature control Trick?

Mercedes were of course venturing a

little into the unknown in Hungary having been excluded from the

Young Drivers test where other teams had, had the luxury of testing

the new tyres. They could however take solace in the fact that the

construction is the same as Pirelli provided in 2012, meanwhile the

Italian tyre manufacturer were also able to share the data collated

by their engineers at YDT. Tyres have been the bane of Mercedes

existence since their rebirth in 2010 but no more so than this year

with the Brackley squad seemingly being able to hold a candle to

their rivals Red Bull through qualifying. Up until Hungary the team

have performed well on a Saturday but gone backwards throughout the

race as their tyres thermally degraded quicker than everyone around

them. The return to a 2012 construction therefore should have been

music to Mercedes ears with the team able to take a fresh approach to

tyre management.

In light of the change in tyre

construction Mercedes have obviously been working closely with their

wheel manufacturer Advanti. Advanti started working with Mercedes

this year but have plenty of F1 experience having supplied wheels to

Toro Rosso since 2008 (until the end of 2012). The reason I bring

this is up is a possible development made to the rear wheels. Up

until now the team have played with painting the inner face of the

wheel black, this has more to do with heat absorption/dissipation

than aesthetics (See image below). Along with the dotted sections inbound you also note in the image below that a

strip on the face has been definitively marked with a 2 silver bands

set around an inch apart.

Now although the above image was taken during the Hungarian GP weekend the following image also surfaced (Thanks to @F1Talks for the heads up)

This image shows the team have reverted to a normal finish on the inner face of the wheel but what does remain is the roughly 1 inch strip toward the inner shoulder of the wheel.

As we can see in the image above a much larger bead/lip defines the edge of this strip on these wheels, now both @F1Talks and many of the folks over on F1Technical.net's forum are concluding that this is indeed an aperture in the surface of the wheel (as indeed did I at first glance, until I looked deeper at the past design of the Mercedes wheel). Now going from what the eye see's (or perhaps wants to see) that could be one explanation with an inner structure of the wheel allowing airflow to permeate the inner structure of the wheel thus cooling the wheel and in turn the tyre. It's a fanciful notion perhaps but could a double skin within the wheel not only be strong enough to cope with the forces at hand but also allow air to transfer from one chamber to the other dissipating the heat?

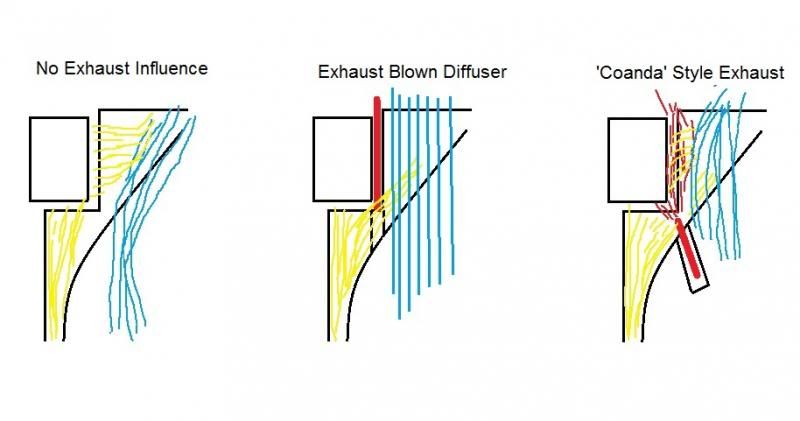

Personally I don't think so I simply believe they have learnt from their experiences so far this season by coating the inner face of the wheel black and adapted it for use with the 2012 construction. Afterall we know that Mercedes decided to drop their 'Coanda' exhaust after Austin last year as they were over heating the shoulders of the tyres. Of course they have developed their 'Coanda' exhaust hugely for use on the W04 but it could still be a concern with a change back to 2012 specification tyres.

Another lesson in perception perhaps with the black strip simply being a coating to the wheel but it is still something that Mercedes are trying in order to reduce the temperatures and therefore degradation this season.

As we can see in the image above a much larger bead/lip defines the edge of this strip on these wheels, now both @F1Talks and many of the folks over on F1Technical.net's forum are concluding that this is indeed an aperture in the surface of the wheel (as indeed did I at first glance, until I looked deeper at the past design of the Mercedes wheel). Now going from what the eye see's (or perhaps wants to see) that could be one explanation with an inner structure of the wheel allowing airflow to permeate the inner structure of the wheel thus cooling the wheel and in turn the tyre. It's a fanciful notion perhaps but could a double skin within the wheel not only be strong enough to cope with the forces at hand but also allow air to transfer from one chamber to the other dissipating the heat?

Personally I don't think so I simply believe they have learnt from their experiences so far this season by coating the inner face of the wheel black and adapted it for use with the 2012 construction. Afterall we know that Mercedes decided to drop their 'Coanda' exhaust after Austin last year as they were over heating the shoulders of the tyres. Of course they have developed their 'Coanda' exhaust hugely for use on the W04 but it could still be a concern with a change back to 2012 specification tyres.

Another lesson in perception perhaps with the black strip simply being a coating to the wheel but it is still something that Mercedes are trying in order to reduce the temperatures and therefore degradation this season.

.png)

.jpg)